İçindekiler

How to Wind a Servo Motor?

What is Servo Motor Winding?

Servo motor winding is the process of rewinding the windings, or coils, inside the motor with wire in accordance with specific technical specifications. These windings are usually located in the stator section and enable the motor to rotate by creating a magnetic field. The winding process is one of the most critical steps in ensuring the efficient operation of the motor and directly affects the performance of the motor, especially in high-precision applications.

Winding that has worn out over time or been damaged due to improper use can cause the motor to malfunction and break down. At this point, the rewinding process comes into play and ensures that the motor is restored to working order. In addition, the rewinding process may be preferred in projects with special design requirements in order to change the characteristics of the motor.

Why is a servo motor wound?

Servo motors are frequently used in automation systems that require precise control and, as a result, may be exposed to excessive loads or environmental effects. Over time, this can lead to issues such as burning of the motor windings, insulation failure, or short circuits. Since replacing the entire motor can be costly in such cases, simply replacing the windings is a more economical and technically sound solution.

In addition, in some cases, the technical specifications of the existing servo motor may be insufficient. For example, higher torque or different voltage may be required. In line with such requirements, the motor winding can be redone according to the desired performance values. Thus, the existing motor is made suitable for the new application.

How Long Does Servo Motor Winding Take?

The winding time of a servo motor varies depending on the physical size of the motor, its power capacity, and the winding technique used. The winding of a small, low-power servo motor can usually be completed in a few hours. However, in large, industrial-type servo motors, this time can extend to one or several working days.

Another factor affecting the duration is the preparatory stages. Removing old windings, cleaning the core, selecting the appropriate wire, and preparing insulation materials can prolong the process. In addition, when testing and drying processes are taken into account, the entire winding process can take several days. Therefore, in order to provide accurate information about the winding time of the motor, the type and damage status of the motor must be analyzed.

How to Wind a Servo Motor?

Servo motor winding is the process of recreating the windings inside the motor according to specific technical specifications. This process is applied when the motor loses performance over time, burns out, or needs to be reconfigured for a specific system requirement. The winding process requires high attention and technical knowledge, as it directly affects the motor’s torque, speed, and control sensitivity. Since the structure of each servo motor may vary, the motor’s operational data and winding characteristics must be carefully analyzed before the winding process begins.

To properly wind a servo motor, the motor is disassembled to expose the stator. The old windings are cleaned, wire of the appropriate diameter and insulation class is selected, and then the new windings are carefully wound. Once the winding is complete, insulation materials are installed, and varnishing and drying processes are applied. Finally, the motor is tested and assembled to ensure it is ready for operation. This process not only restores the motor to working condition but also contributes to achieving long-lasting and efficient performance within the system.

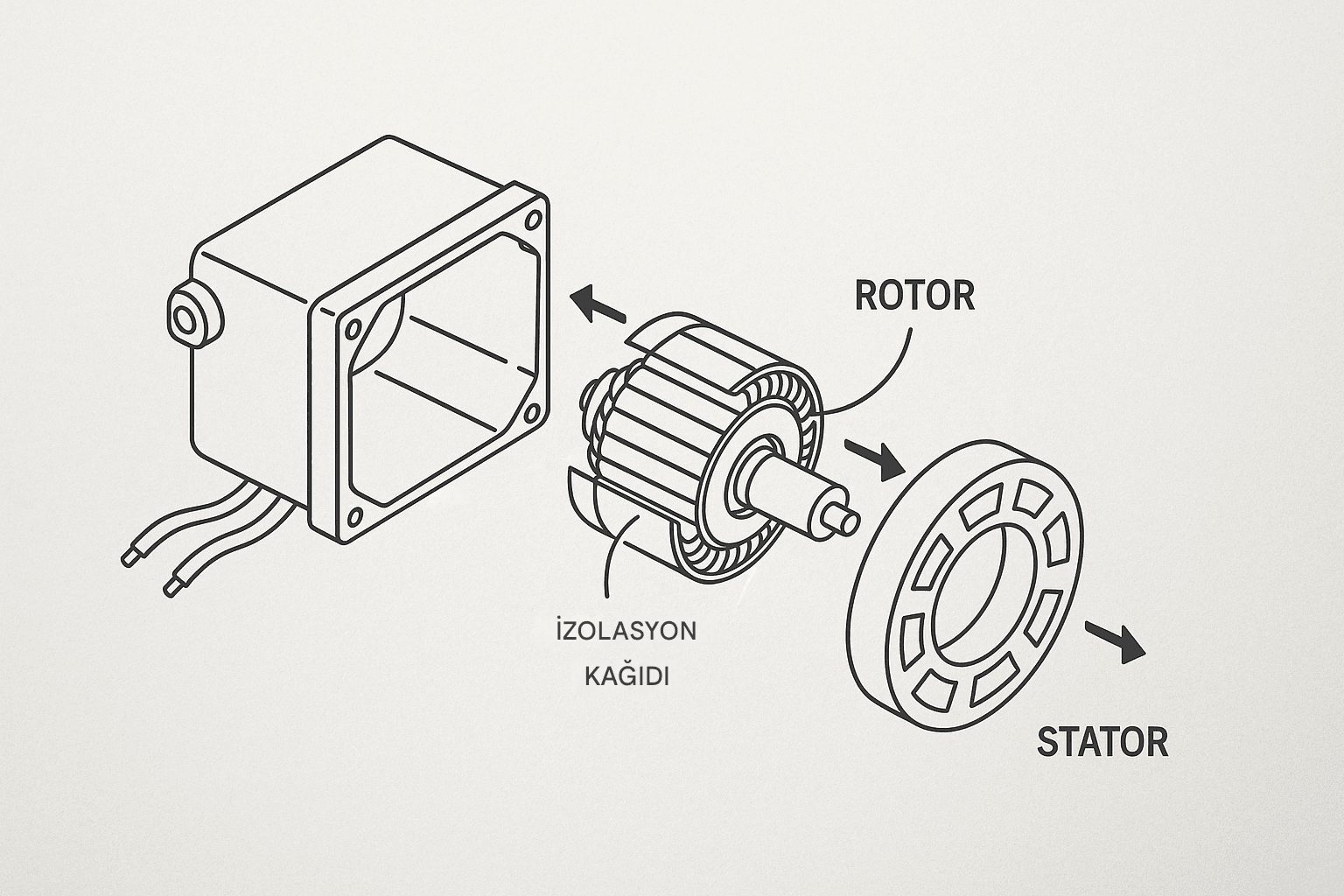

Removing the Servo Motor

Before starting the winding process of the servo motor, the first and most important step is to carefully disassemble the motor. This process must be carried out without damaging the internal structure of the motor. The outer casing connection bolts are removed, and then the motor covers are removed in a controlled manner. When separating the rotor and stator, special tools and hand tools must be used to avoid damaging the internal components. Particularly when removing the magnetic rotor section, failure to exercise caution may result in damage to the bearings or winding slots.

Old windings are usually burnt, discolored, or have damaged insulation. These must be completely cleaned. Burnt wire, resin residues, and insulation papers are removed from the motor housing. During this cleaning process, metal brushes or special scrapers may be used. The slots in the stator must be made smooth and clean for the new winding. The meticulous work done at this stage directly affects the quality of the winding.

Wire Selection and Preparation

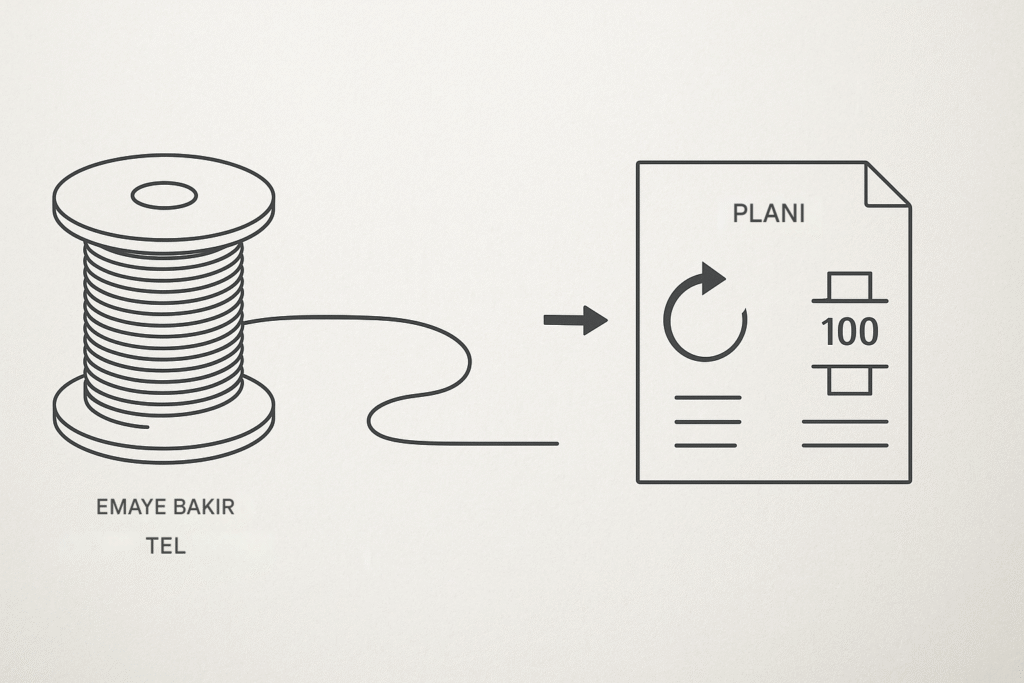

The selection of wire to be used for servo motor winding must be made carefully according to the technical specifications of the motor. The wire used is typically enamel-coated copper wire. The diameter of this wire is determined to be suitable for the motor’s power, voltage value, and desired winding resistance. For motors operating at high temperatures, H-class or higher heat-resistant wires should be preferred. Additionally, the mechanical strength of the wire is also important for long-term performance.

Before starting the winding, the wire must be properly placed on the wire reel and the wire ends must be prepared. If necessary, the enamel on the end of the wire is scraped off to prepare it for soldering. All technical details such as the winding direction, number of turns, and phase structure must be planned in advance. To ensure compatibility with the original motor windings, notes should be taken or schematic drawings should be made before removing the old windings. This minimizes the risk of errors during the winding process.

Servo Winding Process

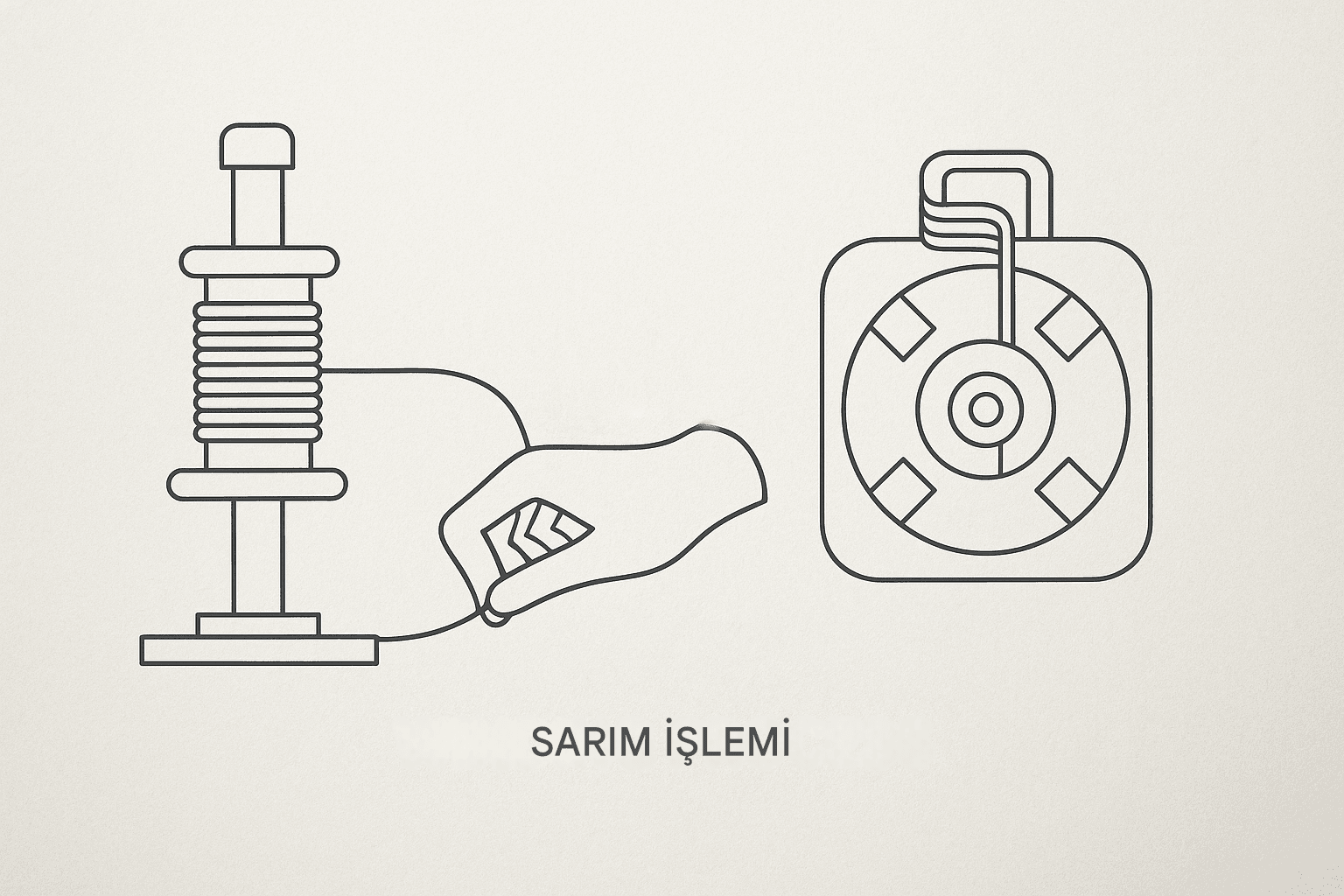

The winding process is a critical step that directly affects the sensitivity and performance of the servo motor. The wire is carefully placed into the slots on the stator. This process can be done manually, or automatic or semi-automatic winding machines can be used. The wire must be placed neatly, tightly, and securely into the slots. During winding, it is extremely important that the enamel coating on the surface of the wire is not damaged in order to maintain insulation.

The number of turns planned for each phase must be completed completely and symmetrically. During winding, the phase ends must be carefully marked, and colored marking tapes can be used to prevent confusion between phases. After winding is complete, all coils should be visually inspected to check for looseness or protrusions. This process ensures that the winding is smooth, which allows the motor to run smoothly and have a long service life.

Insulation and Connections

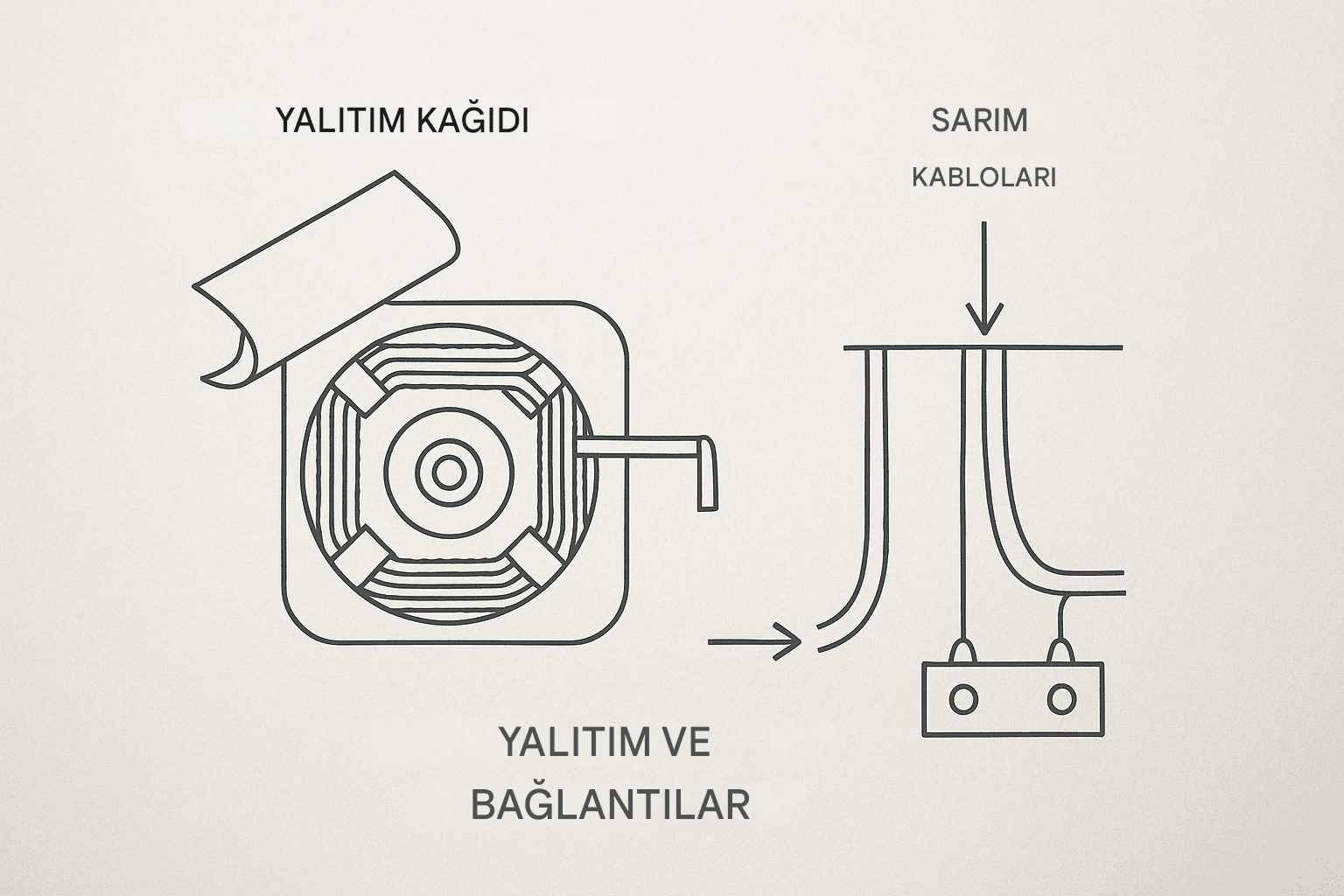

Once the windings are complete, the insulation stage begins. This step is very important for the safe operation of the motor. Appropriate insulation paper is placed between each winding layer and between the stator slot and the wire. Insulation materials must be selected according to the environment in which the motor will operate; they must be resistant to moisture, heat, and vibration. Otherwise, short circuits or leaks may occur while the motor is running.

After insulation, the winding ends are joined and the output ends are prepared. These ends can be soldered or connected to terminal blocks depending on the motor structure. Before making the connection, the enamel coating on the end of the wire must be thoroughly cleaned to ensure a clean surface. After all connections are complete, the phase terminals must be checked individually, and short circuit or open circuit tests must be performed using measurement devices.

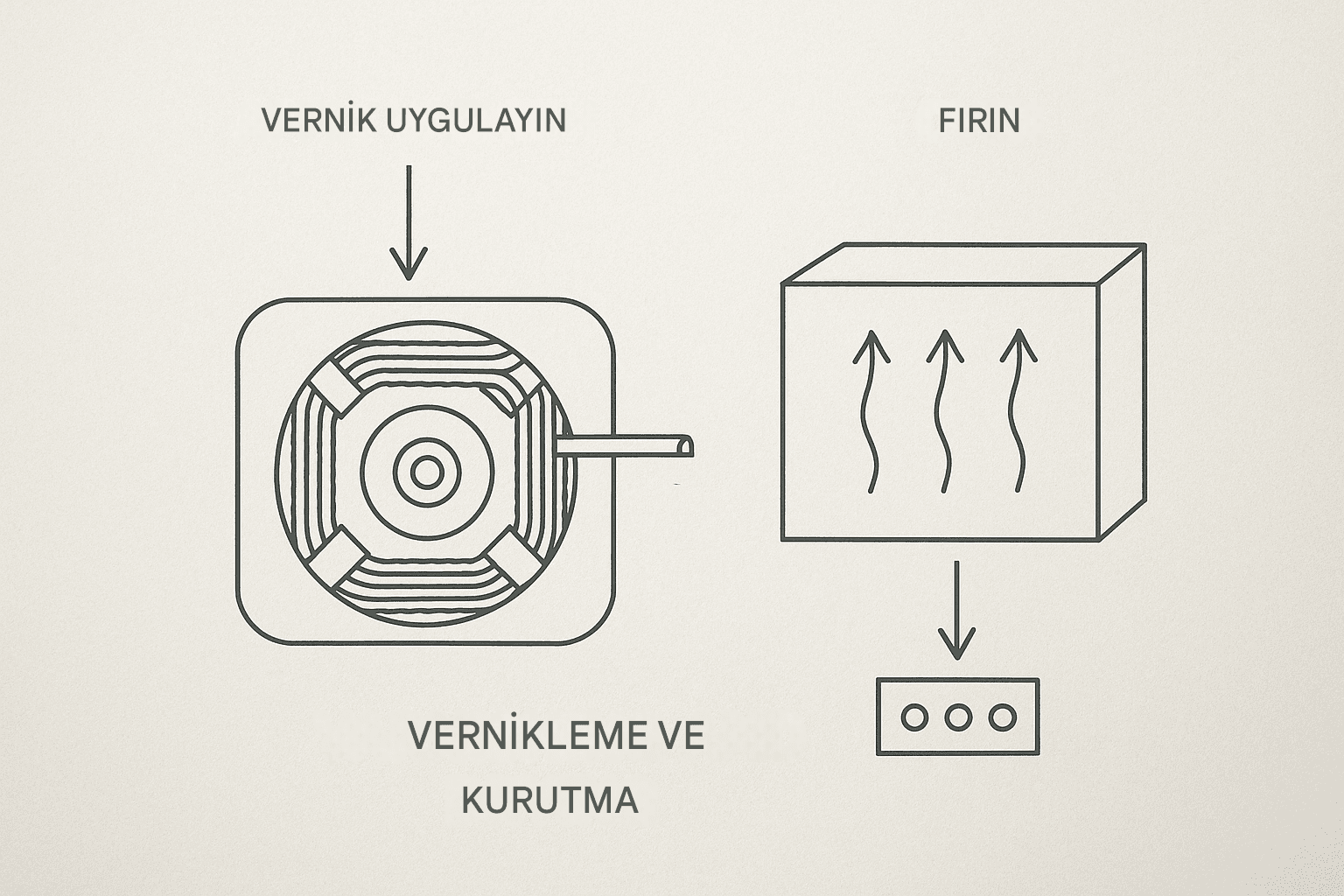

Varnishing and Drying

Once the winding and connections are complete, the varnishing stage begins. The varnishing process is carried out to both strengthen the electrical insulation of the windings and mechanically secure them. The applied varnish helps protect the motor from external factors such as moisture, dust, and vibration that it may encounter during operation. The type of varnish used should be specifically selected based on the motor’s operating environment and temperature range.

After varnishing, the motor is dried in an oven at a specific temperature for a certain period of time. The drying process hardens the varnish and creates a homogeneous insulation layer around the windings. If this step is skipped, the varnish may run over time or become unable to perform its insulation function. Once drying is complete, the motor is ready for testing and proceeds to the assembly process for final inspections.

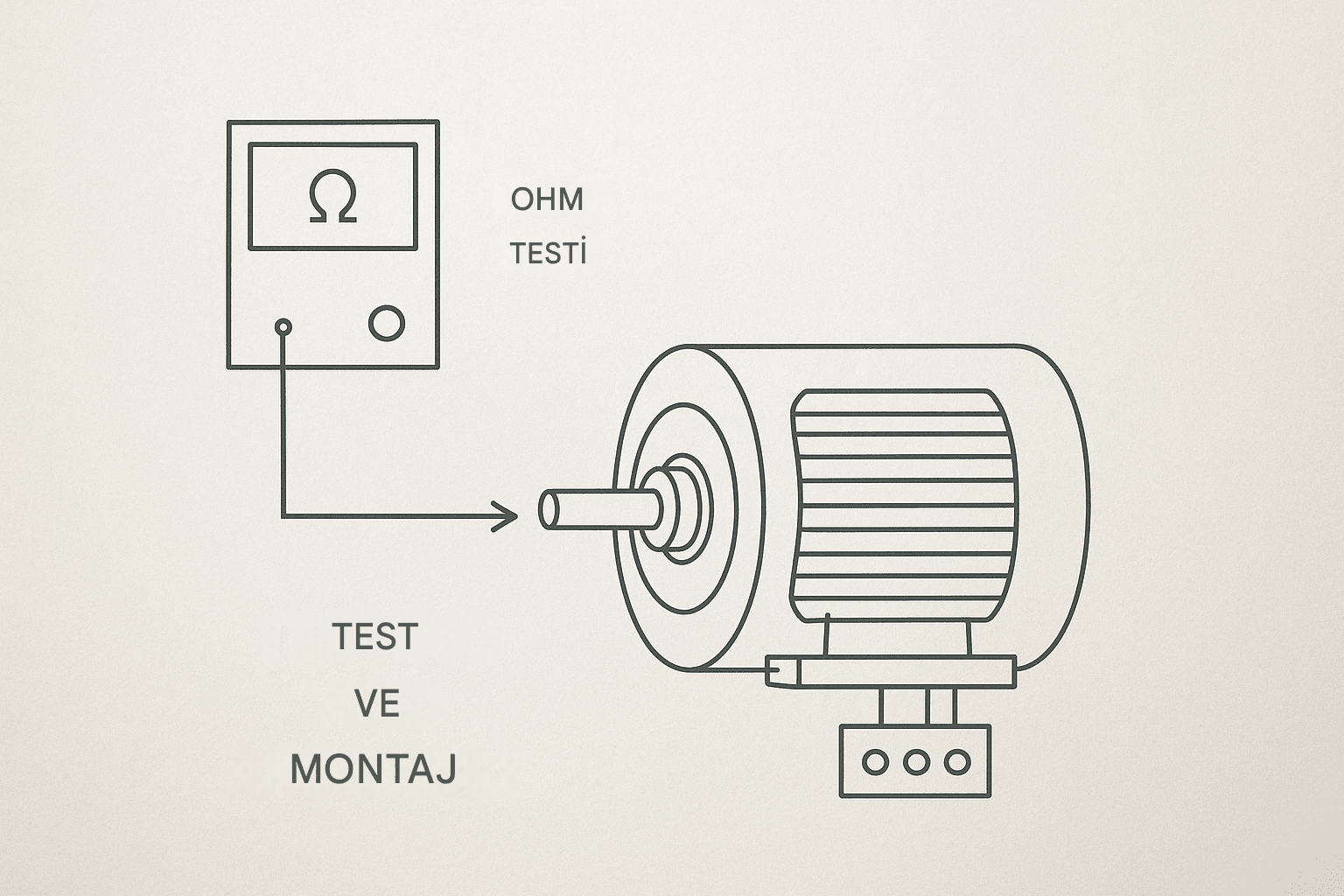

Testing and Assembly

A servo motor with completed winding must undergo various tests before being put into operation. First, the resistance values of each phase are measured with an ohmmeter. This measurement reveals whether there is any imbalance between the windings. Next, the insulation resistance is measured with a megger test. This test shows the level of insulation of the windings against the body and reveals any potential short-circuit risks.

If all tests are successful, the motor is assembled. The rotor and stator are carefully reassembled, the bearings are checked, and the covers are closed. If necessary, new oil is added to the bearings. After assembly, the motor is run idle to check for vibration, noise, and heat. A motor that runs smoothly is now ready for use and can be installed in its intended location.

Servo motor rewinding is a technical process that requires knowledge and experience. However, even though an existing servo motor can be rewound, using a new servo motor is often a more sensible solution in terms of efficiency, accuracy, and longevity. Rewinding may be useful for temporary solutions, but choosing a new servo motor is critical, especially in industrial applications where maximum performance is expected.

Today, technologically advanced, energy-efficient, and low-maintenance servo motors have become the indispensable choice for companies seeking to optimize their production processes. If you want to upgrade your machine park and establish a more stable and powerful motion control system, now is the perfect time to discover the new generation of servo motors.

Diğer Blog Yazılarımız