İçindekiler

Comparison of Open and Closed Servo Step Systems

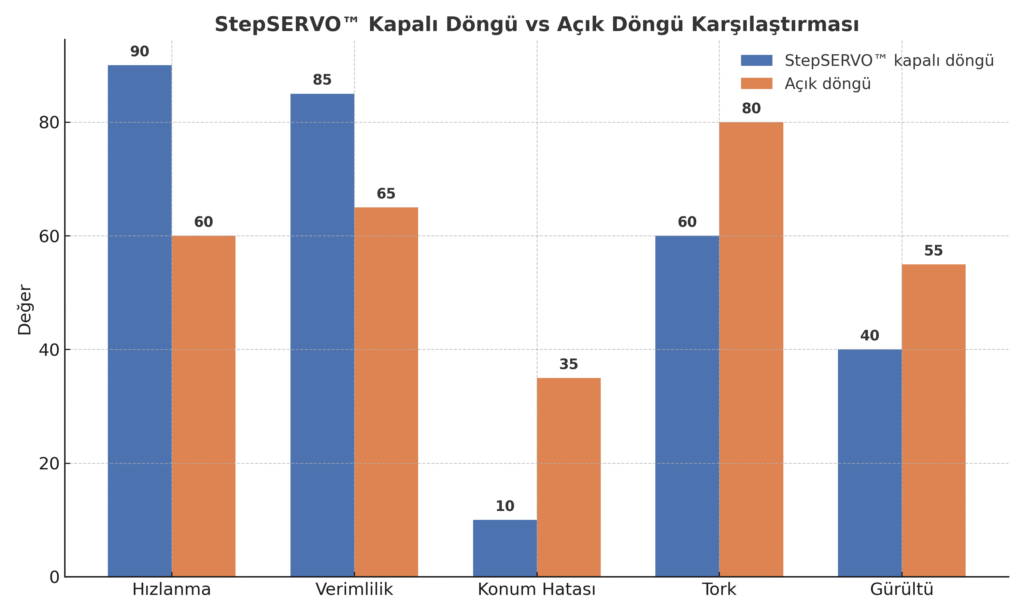

In the world of industrial automation, servo and stepper motor systems are indispensable components for precise motion control. However, the open-loop and closed-loop control structures of these systems create significant differences in performance. Especially in production lines, CNC machines, and robotic applications, the choice of system directly impacts the balance between efficiency and cost.

In this article, we will examine in detail the different classifications of servo and stepper motors, how open and closed loop systems work, their advantages, and their areas of application. This will give you a clearer idea of which motor type to choose for which application.

Different Classifications of Servo and Stepper Systems

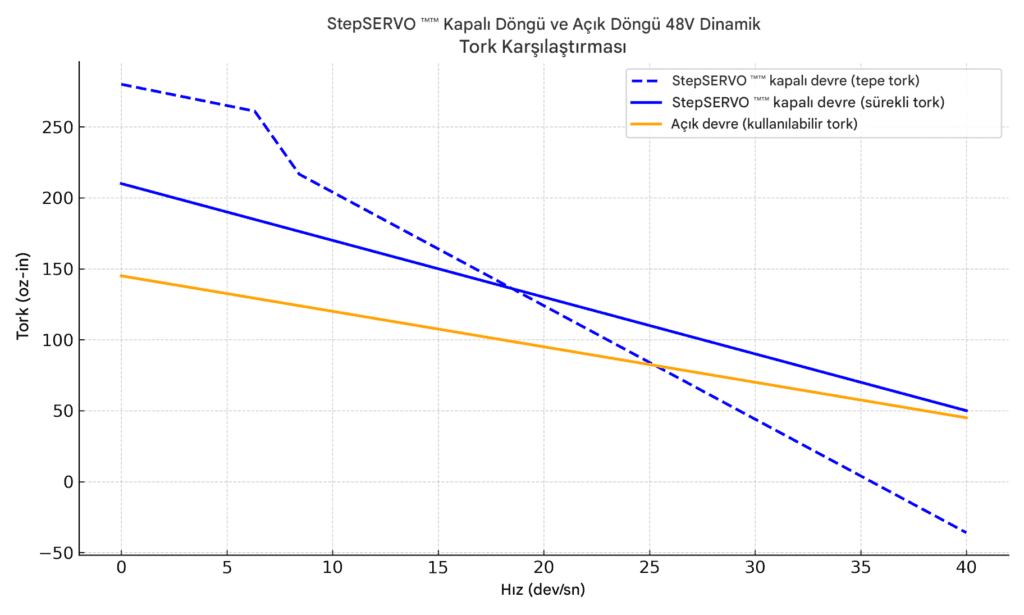

Servo and stepper motor systems are generally classified into two main groups based on their control mechanisms: open-loop and closed-loop systems. In open-loop systems, the motor executes the given command as is but does not receive feedback. In closed-loop systems, however, there is a continuous control loop thanks to sensors, ensuring that the motor operates at the desired position.

In addition, the torque capacities, speed control accuracy, and energy efficiency of servo and stepper motors also make them stand out in different applications. Stepper motors are generally preferred for low-cost, medium-accuracy applications, while servo motors are used in areas requiring higher accuracy and powerful dynamic performance.

What Are Open and Closed Servo Systems?

Servo motor systems offer open-loop and closed-loop options. Open-loop servo systems have a simpler structure; the motor operates according to signals from the control unit, but position verification is not performed. Therefore, they are preferred in some applications where precision is not critical.

In closed-loop servo systems, the motor’s position, speed, and torque are continuously monitored via encoders or sensors. This allows the system to automatically correct any deviation from the target values. This feature makes closed-loop servo motors more advantageous in production environments that require high precision and reliability.

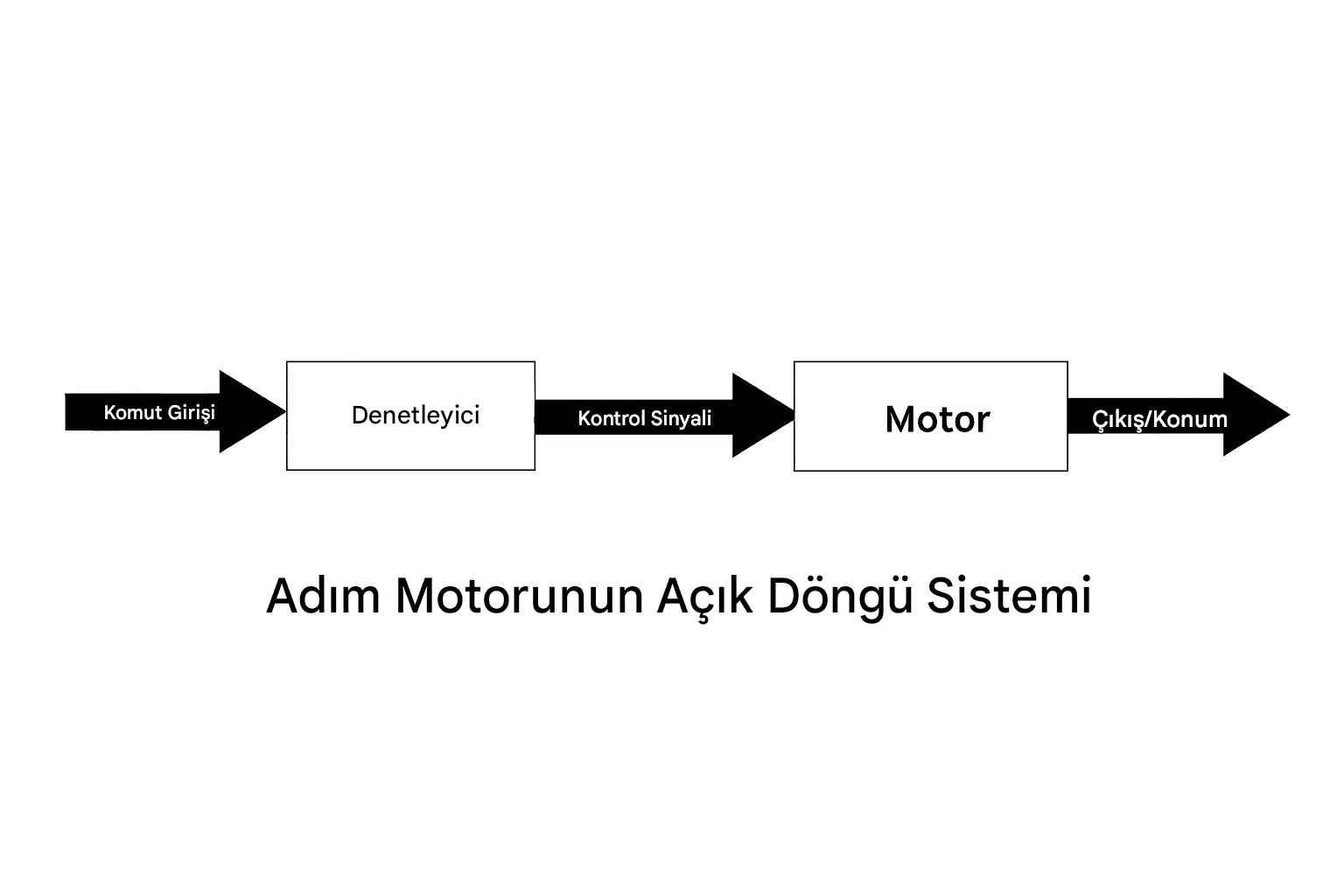

Open-Loop Servo Motor System

An open-loop servo motor system transmits command signals directly to the motor, and the motor executes the given instructions. However, it does not check whether the motor has actually reached the desired position. Therefore, although it is cost-effective, its accuracy remains low.

This system is preferred especially in low-cost automation systems or applications that do not require precision. However, errors that may occur due to load changes, external factors, or the motor’s instantaneous response are not corrected because they are non-feedback, and the system may suffer performance loss.

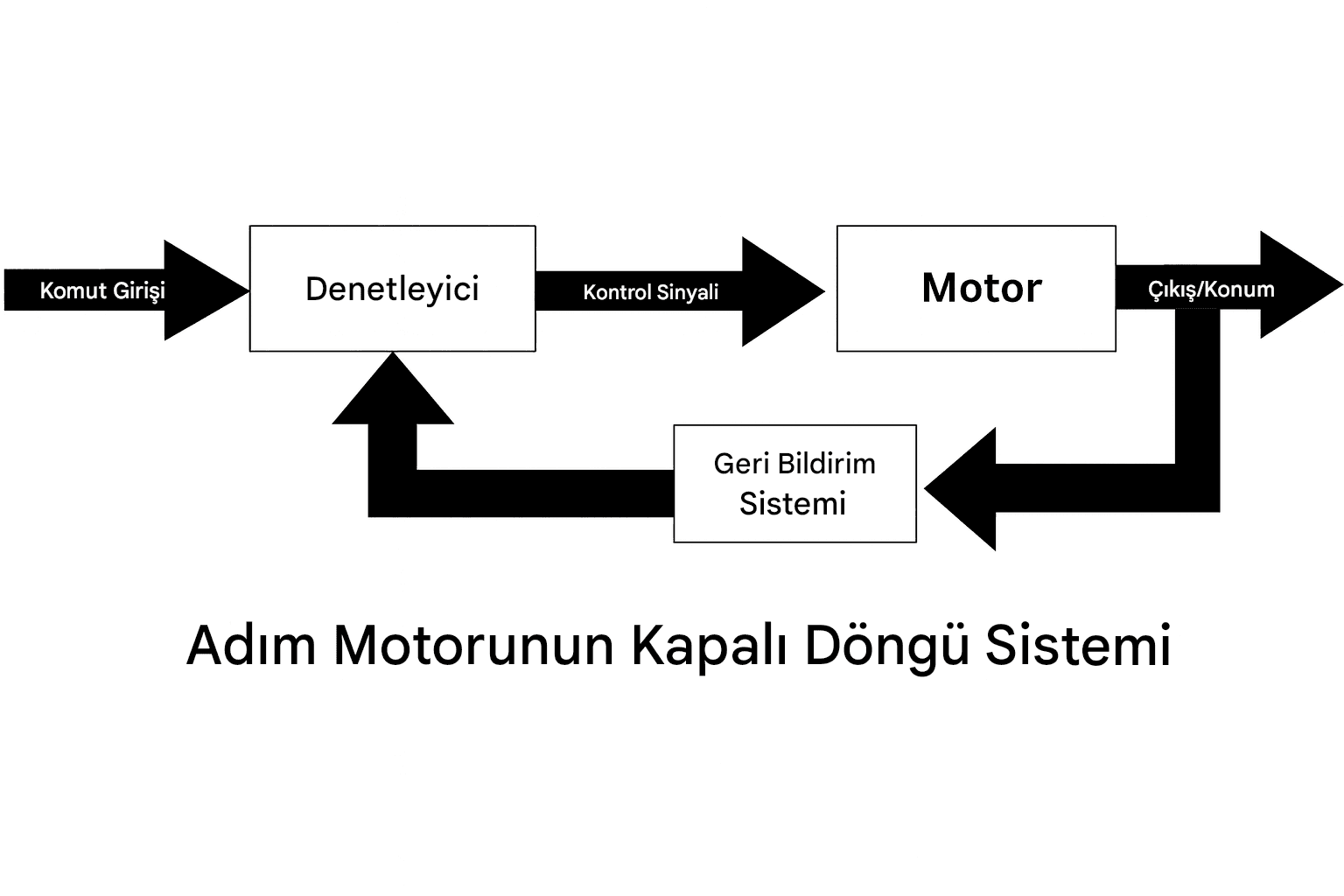

Closed-Loop Servo Motor System

In closed-loop servo motor systems, the motor’s movement is continuously monitored via a sensor or encoder. If the motor deviates from the given command, the control unit immediately intervenes and redirects the motor back to the target position. This ensures high precision and reliability.

These systems are particularly preferred in critical sectors such as CNC machines, robotic arms, medical devices, and automotive production lines. Closed-loop servo motor systems are indispensable in applications requiring high performance and stability.

What Are Open and Closed Stepper Motor Systems?

Stepper motors typically provide position control by moving step by step. In open-loop stepper motor systems, the motor executes the commands given but no position verification is performed. In closed-loop stepper motor systems, movement is controlled with the help of sensors, just like in servo motors.

The performance difference between these two approaches is quite significant. While open-loop stepper motors are sufficient for low-cost and simple applications, closed-loop stepper motors are used in professional industrial projects because they provide high precision and reliability.

Open-Loop Stepper Motor System

An open-loop stepper motor system sends the given signals directly to the motor, and the motor moves according to these signals. It is not checked whether the motor actually reaches the intended position. This situation can lead to synchronization losses, especially at high speeds or under heavy loads.

Open-loop stepper motor systems are sufficient for low-cost 3D printers, simple CNC machines, or some hobby projects. However, in professional production environments, the limited performance of these systems can be a disadvantage.

Closed-Loop Stepper Motor System

Closed-loop stepper motor systems continuously monitor the motor’s movement to prevent step loss. This ensures the motor executes commands flawlessly, eliminating synchronization issues. It also delivers higher speed and torque performance.

These systems are particularly preferred in robotics, medical devices, and CNC machines that require high precision. Closed-loop stepper motor systems offer a solution that combines the simple structure of a stepper motor with the precision of servo motors.

Working Principle of Open Loop Systems

The basic logic in open-loop systems is that commands are sent directly to the motor. Since there is no feedback in this system, control is simple and low-cost. However, external factors or load changes can negatively affect the accuracy of the system.

These systems, which are preferred especially in applications that do not require high precision, are widely used due to their low cost advantage. However, they may be insufficient in situations where high performance and precision are required.

How Closed-Loop Systems Work

In closed-loop systems, motor movement is continuously monitored using sensors. The motor is checked to see if it has reached the target position, and any deviation is corrected immediately. This ensures that the system always operates accurately and reliably.

Thanks to this operating principle, closed-loop systems are widely preferred in industrial production, automation, and precision devices. Their high performance and reliability advantage is the most important feature that distinguishes them from open-loop systems.

Advantages and Limitations of Open-Loop Systems

The biggest advantage of open-loop systems is their simple design and low cost. Their ease of installation and affordability make them attractive for small-scale projects. They also have very low maintenance requirements.

However, its limitations should not be overlooked. Sensitivity is low due to the lack of a feedback mechanism, and performance loss may occur during load changes. Therefore, it may be inadequate for professional industrial applications.

Advantages and Limitations of Closed-Loop Systems

Closed-loop systems offer high precision and reliability. Since motor movements are constantly monitored, there is no loss of position. They also provide flexibility against load changes and can operate stably even at high speeds.

However, these systems are more expensive and can be more complex to install. They also require more maintenance and servicing than open-loop systems. However, in applications where precision is critical, these disadvantages are often overlooked.

Areas Where Open-Loop Systems Are Used

Open-loop systems are commonly preferred in low-cost applications where precision is not critical. Examples of such systems include 3D printers, small CNC machines, automatic doors, and hobby projects.

The simplicity and cost-effectiveness of these applications provide sufficient performance for users. However, they are limited in more complex and demanding projects, so alternative solutions are preferred.

Areas Where Closed-Loop Systems Are Used

Closed-loop systems are used in areas requiring high precision and reliability. CNC machines, robotic arms, medical devices, and industrial automation lines are the main areas of application for these systems.

Closed-loop systems are also frequently preferred in production lines in the automotive industry and in electronic assembly processes. High precision, low error rate, and reliability make these systems stand out.

If you are looking to purchase servo motors or stepper motors for your machinery, automation, or production processes, you’ve come to the right place. Selecting the most suitable motor for your application can sometimes require technical knowledge. At this point, our expert team will assist you in determining the most efficient and durable motors for your project’s needs.

Thanks to the wide range of products available on our website, you can easily compare servo and stepper motors with different torque values, speed options, and accuracy levels to find the model that best suits your needs. You can either contact our experts for technical advice or add your preferred motor directly to your cart and purchase it with fast and secure payment options.

Every product you purchase is backed by our quality guarantee, and we continue to support you with after-sales technical support. Contact us immediately to select the servo motor or stepper motor that suits your needs, or browse our products and complete your purchase with confidence.

Diğer Blog Yazılarımız